Needle shut-off (NSO) nozzles are used to process thermoplastics and liquids. Clean shut-off of melt and reliable closing during metering are the functions of an NSO nozzle. With the shut-off nozzle SYSTEM ENG ® was realized a professional single hole NSO, that meets all requirements for a trouble free and economic production of injection moulded parts.

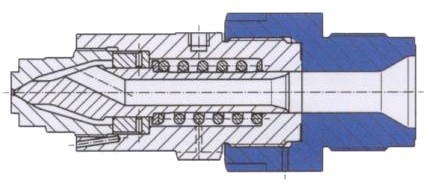

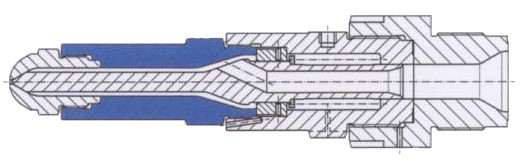

The Needle shut-off nozzles SYSTEM ENG ® are obtainable in two types:

Easy construction

From few parts manufactured the NSO nozzle SYSTEM ENG ® offer substantial advantages in the handling

Þ Easy assembling

Þ Quick and easy cleaning

Þ Trouble free production

Single hole technology

The melt is led central by the nozzle needle

Þ Minimal pressure drop

Þ Optimised heat transport

Þ No shearing of melt

Modular system

Specific adapter for any client. The nozzle is always the same and is available from stock. This means shortest delivery time

Þ Quick change of nozzle

Þ Shortest delivery time

Þ Most economic solution

Shut-off in the nozzle tip

Þ No sprue, no drooling

Þ Controlled, clean shut-off of the melt stream

Þ Reduced cycle times

Compact design

Þ less space

Flexible system

For a fast changeover to various tools and machines there are available different tip lengths from stock

Þ Different penetration

Þ Same nozzle tip